Description

DESCRIPTION

Can accommodate from 1 to 4 lamps, and are available in widths up to 60 inches. These fixtures, complete with UV lamps, can be placed over and under conveyor lines to reduce any mold or bacteria from food, films, or container surfaces, prior to packaging. If the application calls for a custom solution, our engineering department will design a system specifically for your facility or production line with a UV dose targeted to achieve a significant reduction of pathogens. Destroying mold and bacteria on the product, and from packaging material, has been shown to dramatically increase the shelf life of certain products.

Other Models

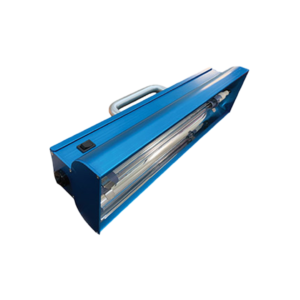

GRMT Series Lights

Have been recently redesigned, provide a stainless steel chassis with a polished aluminum reflector. Guard rails, moisture proof lamp connections, and shatterproof coating on all of the lamps comes standard for the GRMT series. These fixtures, which are available in all voltages, can be mounted on walls, ceilings, over conveyors, or in moist areas where surface disinfection is needed.

In-Duct DC Series Lamps

Ideal for processing and packing areas. They can be installed in the HVAC system, or supply ducts, to reduce or eliminate mold and bio-film build-up on the cooling coil, and in the air flowing through the system.

UVC Germicidal Fixtures for Liquid Storage Tanks

If any part of your food or beverage manufacturing operation involves storing sweeteners like High Fructose Corn Syrup (HFCS), or water, to be used as ingredients in your products, then you are aware of the difficulty in keeping the headspace in your storage tanks and storage tank vents free from microbial growth. Particularly with the dark, moist, warm environment of nutritive liquid sweeteners, you face the obstacle of combating this ideal microbial growth environment. Regular cleaning of your liquid storage tanks is certainly a great start to maintaining your liquid ingredients, including HFCS, as intended, but what about the headspace at the top of the tank? What happens when you drop out product and it is replaced by ambient air from inside (or outside) your facility? How do you ensure that that air is free from bacteria, viruses and mold spores? That’s where American Ultraviolet’s line of liquid sugar storage tank conditioners will help.